30.7 – Technical Evaluation Guidelines for Screw Compressors:

Standard:

Generally, screw compressors are specified and manufactured as per manufacturer standard for compressed air service.

Gas screw compressors are manufactured as per API 619 for compressor and API 614 for oil system.

Following are the evaluation criteria:

1. Vendor should be asked to submit the following:

- Basis for selection of offered model.

- Selection chart

- In case of critical service, references of supply for selected model for the process medium and process operating conditions.

In case of oil lubricated screw compressors, the oil content in ppm at discharge of compressor. Generally, all refrigerated screw compressors are oil flooded type. Air screw compressors can also be oil lubricated type provided oil in outlet air is acceptable.

Dry type are also available for process services and for compressed air service.

2. Control method of achieving minimum turndown should be provided by vendor.

3. If vendor is offering compressor with economizer, check the following:

- Duty and area provided for economizer are consistent with respect to in/out conditions

- Operating conditions with respect to pressures and temperature of the economizer for shell and tube side

- Ensure that oil removal boot is provided in economizer shell side

4. Consumption figures:

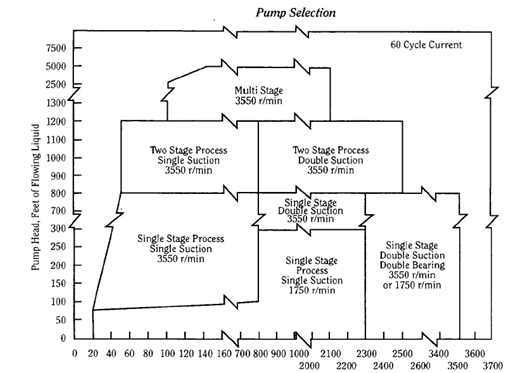

- Refer compressor chart and cross check the power requirement for model selected.

- Minimum turndown and power consumption at part load conditions to be checked.

5. Oil Circuit:

Oil circuit for compressor should be checked carefully and following points must be checked:

- To minimize possibility of cavitation of oil pump, pump should be located at the lowest elevation of oil circuit. Suction pipe for pump should be properly sized. Length of suction pipe should be as minimum as possible. Vertical loop on pump suction line must be avoided, otherwise, oil pump may cavitate because of separation of dissolved gases from oil at pump suction.

- Volume of oil separator should be checked and ensure that 70% of the capacity of oil separator is adequate to receive all oils from crank case and other parts of oil circuit.

- Duplex type filter with change-over facility equipped with all necessary instrumentation like differential pressure indicator, is generally recommended. Downstream of filter upto compressor should be in stainless steel material.

- Requirement of pre and post lube operation for compressor should be clarified by vendor. In case when vendor recommends post lube, immediate restart may become difficult because the compressor gets flooded with oil and oil separator gets empty.

- Tube bundle of oil cooler must be of stainless steel. This is required to avoid formation of water oil emulsion when tube fails due to corrosion and pressure in cooling water is higher than oil pressure.

- Vendor must be asked to provide two oil pumps (1 W + 1 S).

6. Motor Selection:

Vendor shall be asked to indicate power requirement when suction gas density is maximum.

Selected motor should have minimum 15% margin over gauranteed power requirement and over power requirement for maximum suction gas density condition whichever is higher.

7. Review the reference list for quoted model and ensure that said model has already been installed elsewhere and it is working satisfactorily for more than two years.

8. From consideration of maintenance and inventory control, single stage machine is always preferred and more common. If vendor has quoted for two stage machine with intermediate bearing, then thorough investigation of the model is necessary including downtime for maintenance. It has been noticed that time required to dismantle the machine to replace any parts or to align the rotor for single stage machine is much less than that for two stage machine.

9. For oil lubricated compressors, oil used for machine should not be reactive towards gas handled by machine.

10. Instrumentation and Interlocks:

11. Ensure that following minimum interlocks have been considered by vendor. Compressor should trip under following interlocks:

- Low low suction pressure

- High high discharge pressure

- High high discharge temperature

- Low cooling water flow (for water cooled machines)

- High level of economiser and low & high level of oil separator

- Low lube oil pressure

- High lube oil temperature

- Low lube oil differential pressure

ii) All instrumentation and controls other than shut down sensing devices shall be installed with suitable isolations and controls while system is in operation.

iii) Necessary instruments to provide alarms before trip should be included

iv) Instrumentation for compressor control (if included in enquiry should be in vendor scope).

Mihir’s Handbook at just USD 2.0/ebook (India: Rs.150/ebook)